After browsing loads of blogs I started finding science journals for more in depth information. Lots can be found in that kind of information too. Other sources are International standards, laws, guidelines from the industry, websites of distilleries, and pages about wine, port, beer and general brewing.

What did I learn? Here is a short overview of what I learned so far.

Laws prescribe the use of wood in Europe when maturing whisky. In the USA similar laws exist. Scotland also has laws that prescribe the use of wood, particularly only the use of oak.

The time spend in the barrel also has minimal times set to it by law. Depending on the laws and the nations the minimum time differs.

Other laws prescribe the content of the mash bill, thereby setting guidelines for types of whisky. This is mostly done in the USA.

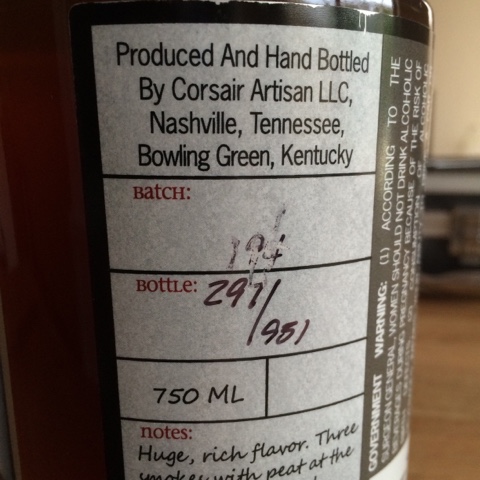

Barrel size influences the speed of chemical processes in a barrel. The speed of these progresses can be, but should not always, be presumed equal to aging or maturation.

The previous content, if any, of the barrel influences the chemical compounds already present in the barrel. It therefore influences the chemical processes that still can happen or that would otherwise not happen. Other chemical processes will not happen anymore, since the reactants have already reacted with the previous content.

The way the barrel is stored influence the open space and the shape of the open space above the liquid in the barrel. Gasses like oxygen will react in different speeds depending on this. The orientation of the barrel in storage, upright or on its side, influences the exploded surface therefore influencing the taste over time. If the bung is in contact with the spirit influences the taste and "water tightness". Most bungs are not made from oak. Oak is to hard for use as a bung.

Oak has particular properties that no other woods has, also on a cell base level, that influence the absorption of liquid and the blocking of liquid. This is dependent on the part of the tree the oak is taken out of. Near the centre is normally not used since this is where the sap flow is. The oak also influence the gasses able to get into the barrel from the outside and from the inside out.

The inside of the barrels are often, but not always, influenced by fire or heat. In the USA this is called charring and differently than in Europe where it's called toasting. Different levels of exposing to heat start different processes in the wood. This results in different chemical processes that will or will not happen over time. The carbon layer acts like a filter, just like an active carbon filter does in a breathing apparatus.

The type of grain used can be combinations (mash bill) or just one kind of grain. The biological build-up of these grains result in different reactions taking place throughout the processes used to make and mature whisky. Compounds not present in one grain will not be able to react and will therefore influence the end result.

The yeasts used influence the outcome in a similar way. Yeasts are described in strains and kinds.

The tools used to distil influence the outcome. This is a field on its own but not well documented in science. Science does describe the reactions between heated, evaporated and condensed spirits and the used tools. Copper in the evaporation parts of the stills have a filtering function by combining with sulphur.